How Harlan Estate Unifies a Napa Trilogy

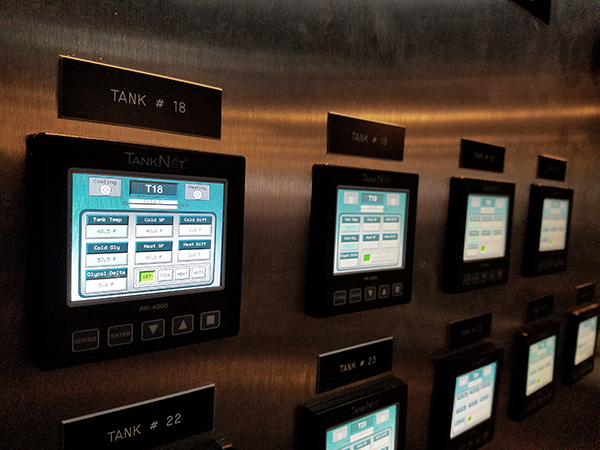

In the world of viticulture, the name Harlan Estate is synonymous with a relentless, near-obsessive pursuit of perfection. This ethos extends beyond the vine and into the cellar, where the "trilogy" of Harlan's Napa Valley properties - Harlan Estate, Promontory, and BOND - now operates under a single, sophisticated digital ecosystem: TankNET®.

To produce wines of such profound character and longevity, the technical team required more than just automation; they needed a system that understood the delicate biological rhythms of fermentation.

Gentle Fermentation

Eliminating Thermal Shock

The most critical phase of winemaking is the most volatile. Traditional cooling systems often use a "sledgehammer" approach, hitting warm fermentation tanks with freezing glycol. This creates thermal shock at the tank wall, which can arrest yeast activity and cause stuck fermentations.

Harlan's TankNET® solution utilizes a Variable Delta-T control strategy. Rather than a fixed coolant temperature, the system continuously monitors the wine and adjusts the glycol supply temperature in real-time. By maintaining a precise, gentle temperature differential between the wine and the coolant, TankNET® ensures:

- Yeast Viability: Fermentations remain steady and healthy without abrupt interruptions.

- Kinetic Control: Winemakers can guide the "arc" of the fermentation with exacting precision.

- Supple Tannins: Gentle cooling preserves the elegant mouthfeel and structural integrity essential to the Harlan profile.

A Unified Atmosphere

From Tank to Barrel

The scope of the TankNET® installation across the three wineries goes far beyond the fermentation tank. It acts as the central command for the entire facility's environment, managing:

- Barrel Room Stabilization: Precise control of humidifiers and air handlers to minimize the "angel's share" (evaporative loss) during aging.

- CO2 & Safety: Automated management of louvers and exhaust fans to ensure worker safety during peak fermentation.

- Workplace Comfort:Seamless integration of HVAC across tank rooms, barrel rooms, and general work areas.

Demand-Based Intelligence

Efficiency at the super-premium level isn't just about cost - it's about reliability. TankNET® serves as the operational core for the entire mechanical suite, including multi-stage chillers, circulation pumps, gas-fired boilers, and air compressors.

By communicating directly with the mechanical plant, the system dictates operation based on real-time load. This prevents the "short-cycling" that leads to mechanical fatigue, ensuring that during the high-stakes weeks of harvest, the equipment performs flawlessly.

Results

Full control via secure web browser, from any location.

Complex metrics converted to graphical decisions in real-time.

The entire winemaking team sees the same data, simultaneously.

Harlan Estate represents a standard of excellence where every detail is a deliberate choice. By unifying Harlan Estate, Promontory, and BOND under TankNET®, we've matched their world-class viticulture with a world-class digital architecture.