Precision in Practice

How Opus One Orchestrates the Perfect Ferment with TankNET®

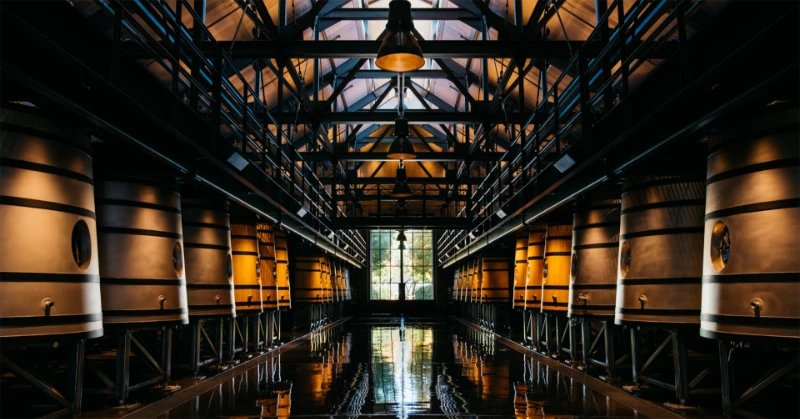

At Opus One, the pursuit of absolute quality is a discipline that bridges generations of tradition with the forefront of enological science. For a winery dedicated to creating a singular, age-worthy vintage each year, consistency is not just a goal - it is a requirement. To maintain this standard across every lot, Opus One relies on TankNET® for complete thermal visibility, precise automated control, and real-time fermentation insight.

Eliminating Blind Spots

Winemaking at the highest level requires seeing the unseen. Standard tank controls often treat fermentation as a single data point, masking the complex realities inside the vessel. Stratification, heat pockets, and subtle shifts in yeast metabolism can alter the trajectory of a wine long before traditional sampling methods catch them. Opus One needed a system that could match their rigorous attention to detail - providing granular data and responsive control to ensure every tank expresses the estate's terroir exactly as intended.

A Complete Fermentation Ecosystem

By integrating TankNET®'s comprehensive control platform, Opus One has transformed fermentation from a monitored process into a precisely managed ecosystem.

- Thermal Clarity & Consistency: Using multi-point temperature sensing, the winemaking team gains a complete thermal profile of each tank. This technology reveals stratification and hot spots that single-probe systems miss, allowing for more accurate decisions regarding cooling, mixing, and cap management. Paired with pulse-cooling, the system maximizes heat transfer efficiency by cycling glycol flow. This reduces energy use and eliminates temperature overshoot, ensuring the stable conditions necessary for premium yeast performance.

- Real-Time Insight & Kinetic Control: Waiting for daily manual samples can mean missing critical windows for intervention. TankNET®'s real-time Brix measurement delivers continuous visibility into sugar depletion and fermentation rates. This allows the team to detect sluggish ferments early and adjust temperatures with data-driven precision. Furthermore, the integration of REDOX sensors provides a window into the electrochemical balance of the must. By monitoring yeast health and oxygen levels in real time, the team can predict and prevent reduction issues before they manifest as sensory faults, ensuring a clean, fault-free finish.

- Automated Precision: Consistency in extraction is vital for the structure of Opus One's blends. Automated pump-overs - enhanced with optional Venturi aeration - deliver precisely timed oxygen exposure and consistent mixing. This optimizes cap management and yeast performance while reducing the manual labor and variability associated with traditional pump-over methods.

Results

Confidence from Anywhere

The power of TankNET® lies in its ability to synthesize complex data into actionable control. By presenting all fermentation metrics graphically in real-time via web-browser software, TankNET® gives the Opus One winemaking team shared, immediate visibility. Whether standing at the tank or monitoring from a remote office, the team can make fast, confident decisions, coordinating control across every vessel to ensure the vintage reaches its full potential.

TankNET® gives us the shared visibility and data-driven control we need to ensure every fermentation meets our standards - consistent, precise, and true to our vision.