Customers Worldwide

+350

North America

+50

International

30 → 100

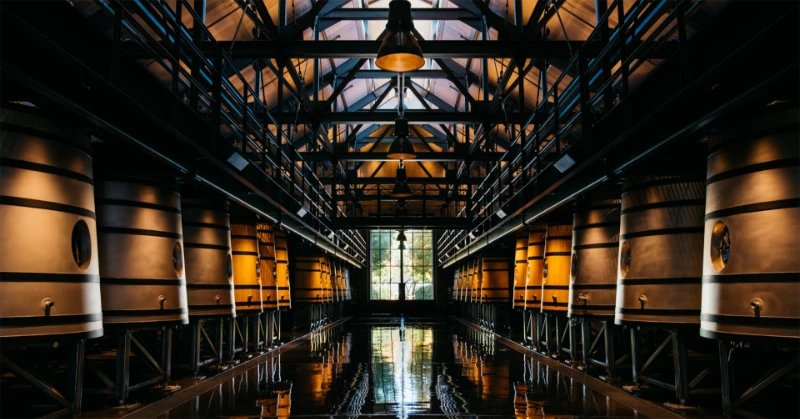

“With the automatic pumpover system, we went from 30 pumpovers per batch to over 100, at a steadier pace, not just squeezing them in. The result was richer color, more concentration, and better homogenization of aromas and flavors.”

Let's discuss your project.

Every facility is unique. Contact us to discuss your infrastructure and control needs, and we will recommend the solution that balances cost, aesthetics, and functionality.