TankNET® Pro

Fermentation Control & Winery Integration

Advanced Features, Accessible From Anywhere

TankNET® Pro is an affordable and intuitive web-based control solution designed specifically for mid-to-large sized production facilities. It enables teams of any size to precisely manage tank fermentations, optimally control critical plant equipment and cellar environments, and monitor energy usage across multiple locations.

TankNET Pro also integrates with common building automation systems and popular 3rd party software such as Vintrace, Breww and others. This enables winemakers and maintenance staff to work together to better maximize wine quality while minimizing equipment down time.

Accessible from any web-browser, iOS or Android device, TankNET Pro truly puts you in control, and in the know from anywhere.

I use TankNET® extensively to help deliver on the promise of each vintage.

--Cory Empting, Harlan Estate

All the features of TankNET® Lite plus:

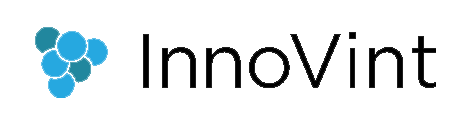

Cellar Maps

TankNET® Pro presents a birds-eye view of your entire winery through custom navigation and detailed cellar maps. This provides authorized users intuitive access to all monitored and controlled equipment in the winery.

Animated icons automatically update to display current fermentation data, cellar conditions, refrigeration equipment status and alarms.

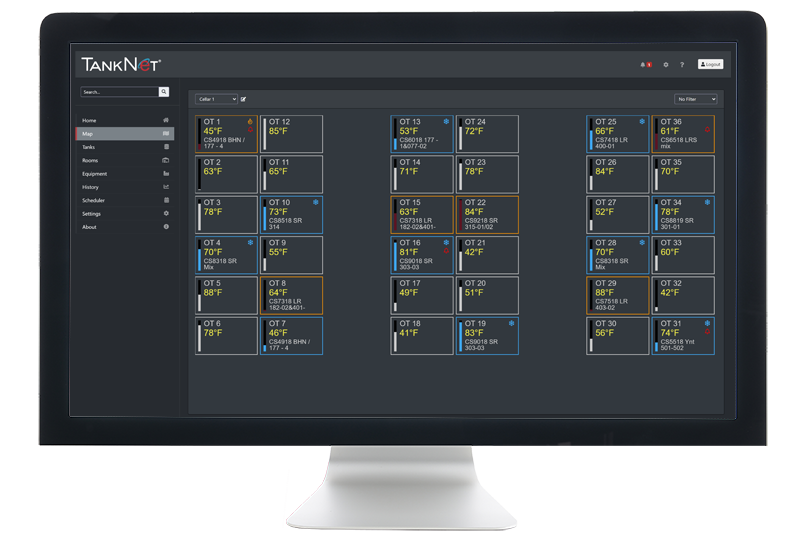

Tank Groups

With TankNET® Pro users can create unlimited personal and shared groups. This provides winemaking teams quick access to tanks and equipment by cellar or area of responsibility.

TankNET Groups are displayed in personalized, sortable, color coded tables, which can be filtered by various criteria. Filters and column sets can be saved and recalled for easy group-wise reporting and editing. View tanks by varietal, lot status, volume (full or empty), alarm state, control status and more.

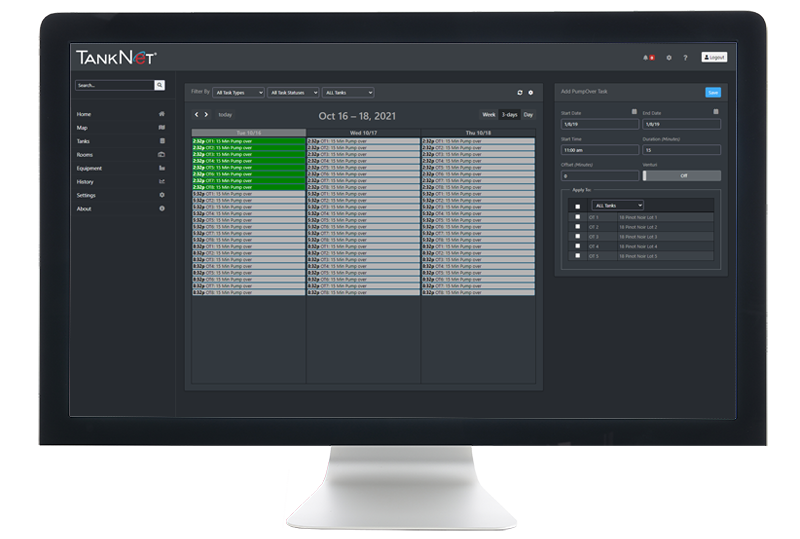

Scheduled Pump-Over & Aeration

Automate pump-overs with optional venturi for any number of tanks. Schedule pump-overs based on date-time or trigger them dynamically using brix, fermentation status and/or temperature stratification.

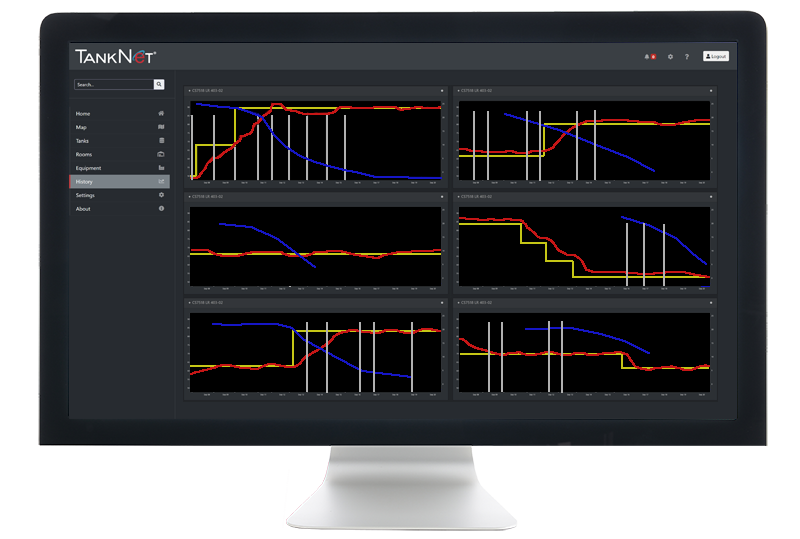

Fermentation Reports

Track, graph and report all aspects of each fermentation. Unlimited data capture including brix, temperature, pump-over and aeration, lab data, tasting notes and data from 3rd-party winery production software.

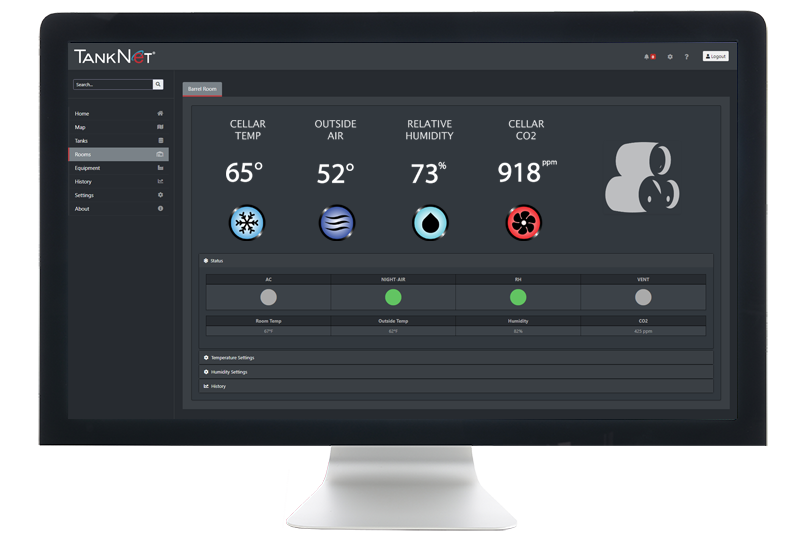

Cellar and Barrel Room Control

Precisely and efficiently control your cellar and barrel room environments with TankNET®. Integrate 3rd-party fan control panels or use a TankNET® PM-Series purpose-built controller to manage cellar temperature, humidity, CO2 exhaust and night-air cooling.

Dynamic Chiller & Heater Control

Dynamically control your glycol heaters and chillers based on actual demand in the cellar. TankNET automatically adjusts equipment set points, pump speeds and compressor staging to achieve optimal efficiency and reduce equipment down-time.

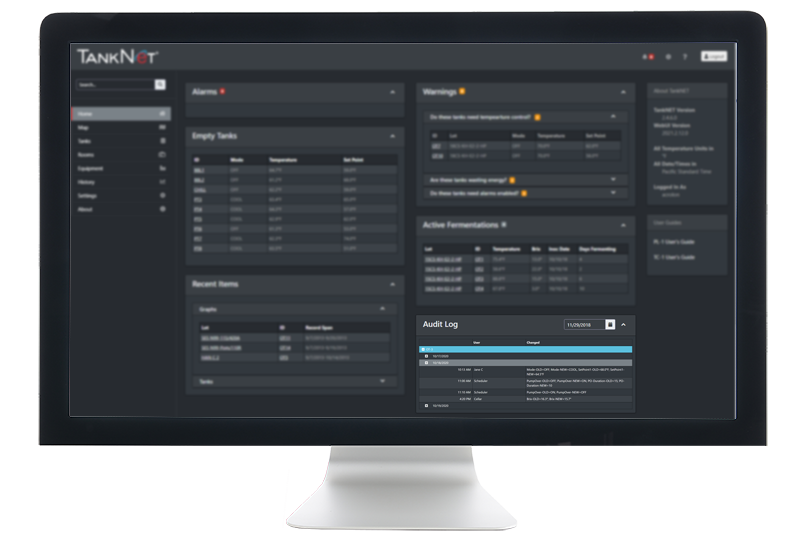

Auditing

Use the audit log to keep track of changes made on the TankNET® system. All updates to settings made either at the controller or through software are recorded and made accessible so you can always see who changed what, when, and from where.